In today's fast-paced manufacturing landscape, ensuring precision in packaging is paramount. Traditional quality control methods often fall short due to their limitations, inherent inaccuracies, and high labor costs. This is where AI-powered vision inspection emerges as a game-changer. By leveraging the power of machine learning algorithms, these systems can detect even the subtlest defects with unparalleled speed and reliability.

AI-driven vision inspection systems analyze high-resolution images or videos of packaged goods, dynamically monitoring for a wide range of anomalies. From misaligned labels and missing components to cracks and tears in packaging materials, these intelligent systems can flag defects with exceptional distinctness. This enables manufacturers to enhance their production processes, reduce waste, and ultimately deliver superior products that meet the stringent demands of consumers.

- By automating the inspection process, AI vision systems free up human workers to focus on more complex tasks.

- Additionally, these systems can provide valuable data analytics that uncover patterns in product quality and manufacturing performance.

- This instantaneous feedback loop allows manufacturers to anticipatorily address potential issues and streamline their operations for maximum efficiency.

Intelligent Visual Inspection : Detecting Defects in Food Packaging with AI

In the competitive food industry, maintaining product quality is paramount. Traditional inspection methods are often time-consuming and susceptible to human error. Intelligent visual inspection using artificial intelligence (AI) offers a reliable solution for detecting defects in food packaging. AI-powered systems can analyze images and videos of packaging in real-time, identifying subtle flaws that may be missed by the human eye. These systems leverage deep learning algorithms to recognize a diverse array of defects, such as cracks, gaps, and color variations. By implementing intelligent visual inspection, food manufacturers can enhance product quality, reduce losses, and build brand reputation.

Empowering Inspection through AI

The field of packaging inspection is undergoing a profound transformation thanks to the implementation of computer vision powered by artificial intelligence (AI). Advanced algorithms enable machines to analyze package condition with unprecedented accuracy and speed. This AI-driven precision allows manufacturers to pinpoint defects and anomalies that might evade human observation, ensuring that only defect-free products reach consumers.

- Consequently, AI-driven inspection systems offer a multitude of perks including:

- Minimized production expenses

- Augmented product reliability

- Amplified operational efficiency

Next-Generation Food Safety: Smart Vision Systems for Seamless Packaging Inspection

The food industry deals with ever-increasing demands for enhanced safety and quality. To fulfill these challenges, next-generation technologies are emerging, revolutionizing the way we ensure food safety. Among these innovative solutions, AI systems are gaining prominence for their ability to conduct seamless packaging inspections.

These sophisticated systems employ high-resolution cameras and advanced algorithms to scan packaging in real-time. By detecting defects, such as cracks, tears, or contamination, AI vision systems help avoid the shipment of unsafe products into the market.

- Additionally, these systems can as well confirm label accuracy and product correctness, ensuring compliance with regulatory standards.

Finally, AI vision systems are transforming food safety by providing a accurate and streamlined means of packaging inspection. By enabling early detection of potential hazards, these technologies contribute to a safer and more trustworthy food supply chain.

Boosting Efficiency and Accuracy: AI's Impact on Packaging Inspection

Smart inspection systems powered by artificial machine learning are revolutionizing the packaging industry. These advanced technologies enable manufacturers to achieve unprecedented levels of efficiency and accuracy in identifying defects, ensuring product quality and consumer safety. By leveraging computer vision algorithms, AI-driven systems can analyze visual data of packages at high speed, detecting subtle variations or anomalies that may escape human perception. This real-time analysis allows for immediate corrections, minimizing product waste and enhancing overall production output. Furthermore, AI's ability to continuously learn and adapt means that inspection systems can become more precise over time, further reducing errors and boosting operational efficiency.

Seeing Beyond Human Capabilities: AI Visual Inspection for Enhanced Food Packaging Quality

In today's highly competitive food industry, maintaining optimal food packaging quality is paramount. Ensuring packages are flawless and meet stringent safety standards plays a vital role in protecting product integrity and consumer trust. While traditional inspection methods rely heavily on human sight, these can be susceptible to fatigue, variability. This is where AI visual inspection emerges as a transformative solution. Leveraging the power of machine learning algorithms, AI systems interpret images with remarkable accuracy, identifying minute defects and anomalies that may escape human detection.

- Therefore, AI-powered visual inspection offers a range of benefits for food packaging manufacturers.

- It improves inspection accuracy, minimizing the risk of defective products reaching consumers.

- Furthermore, it streamlines the inspection process, reducing labor costs and enhancing operational efficiency.

Therefore, AI visual inspection represents a significant leap forward in food packaging quality control. By embracing this technology, click here manufacturers can guarantee the highest standards of product safety and offer consumers with confidence and peace of mind.

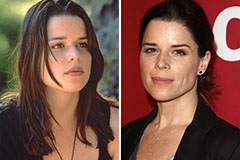

Neve Campbell Then & Now!

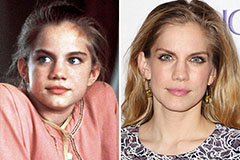

Neve Campbell Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!